Plastic injection moulding is an exceptionally flexible technique of generating plastic components and has several benefits over various other plastic moulding approaches. Not just is the procedure easier but also more dependable than other methods; however, it is additionally incredibly effective.

-

High Efficiency- Fast Production

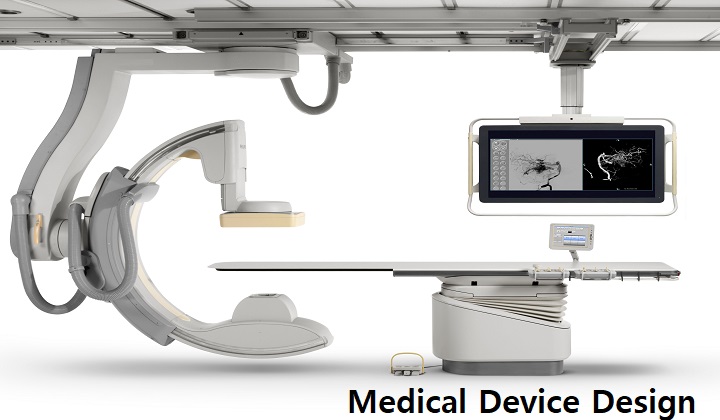

There are numerous great factors that plastic injection moulding is referred to as one of the most typical and most effective kinds of moulde Medical Device Design. The procedure itself is exceptionally quick contrasted to various other approaches, and the high manufacturing result price makes it much more affordable and effective. The rate relies on the mould and mildew's intricacy and dimension; however, just concerning 15-120 secs pass in between each cycle time.

With the brief duration between cycles, a higher amount of mould and mildews can be generated in a minimal quantity of time, raising feasible profits and revenue margins.

-

PERFORMANCE

You'll be functioning with a group that likely has years of experience under their belts if you companion with an advanced injection moulder. It implies that they precisely recognise just how to maximise layout, make your elements in one of the most effective means feasible, and concentrate on the layout upfront to decrease troubles in the future.

-

Improved Strength

When creating a Plastic Injection Moulding formed component, endurance is one of the essential variables that must be figured out. If the element requires to be inflexible or adaptable so that he/she can readjust the incorporating gussets or ribs, the developer will certainly need to understand. Recognising exactly how the client will certainly be making use of the component and the atmosphere the component will be in is a vital subject.

Discovering the appropriate equilibrium of style factors to consider will certainly resolve your component's demand for toughness and security.

-

Capacity To Simultaneously Use Multiple Types Of Plastic

It's not unusual for complicated component layouts to need parts made from various products. Plastics casting from moulder's task can ensure that multiple polymers work under all problems to reduce issues.

-

Adaptability- Material and Colour

Picking the ideal product and shade for a task are 2 of the important consider developing plastic components. As a result of the wide range of both, the opportunities are nearly unlimited. The breakthroughs in polymers for many years have boosted the growth of material choice. It is essential to collaborate with an injection moulder with experience with moulding applications & materials, including the materials certified with the FDA, RoHS, REACH and NSF.

-

Item Development Timeline

From ahead of time layout assistance to mould flow evaluation software program, injection moulding can aid OEMs to accomplish a much shorter item advancement timeline, subsequently speeding time to market.

-

Reduced Labour Costs

Labour prices are fairly reduced in Custom Plastic Moulding, contrasting with various other kinds of moulding. Creating the components at an extremely high degree with a high outcome price assists with its expense performance and performance.

The moulding devices commonly keeps up a self-gating, automated device to maintain procedures structured and manufacturing recurring, calling for marginal guidance.

Related : Plastic Injection Molding- An Innovative Way Of Injection Molding